|

|||

|

|

|

|

Harpak-ULMA stays ahead of packaging trends, offers superior customer service

By Alyssa Mitchell

|

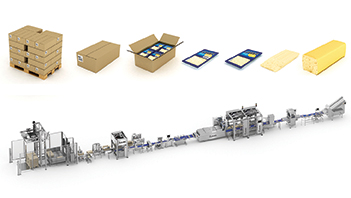

| AUTOMATION — Harpak-ULMA offers full product to pallet automated solutions. This line puts sliced cheese into a thermoforming machine, into cartons and ultimately onto a pallet for transport. |

Photo courtesy of Harpak-ULMA Photo courtesy of Harpak-ULMA |

| AUGMENTED REALITY — Harpak-ULMA offers customers the latest technology, including augmented reality, like Chalk from PTC, which allows remote experts to assist on-site staff with maintenance and troubleshooting. |

TAUNTON, Mass. — Harpak-ULMA is positioning itself as a leading supplier of high-quality cheese packaging solutions for emerging technologies while continuing to offer superior service and support to its customers.

The company, based in Taunton, Massachusetts, offers complete solutions that range from product handling, row distribution and automation to cartoning, casepacking and final placement on a pallet.

Harpak-ULMA offers a wide range of packaging systems including: thermoforming, tray sealing, horizontal flow pack (HFFS (horizontal form, fill, seal)), vertical flow pack (VFFS (vertical form, fill, seal)), shrink wrap, skin pack and stretch overwrap. The company also offers fully automated lines and is the North American distributor of G. Mondini tray sealers and ULMA primary and secondary packaging systems.

The company prides itself on staying ahead of the latest trends to offer its customers the best solutions for their cheese packaging needs. Jerry Rundle, vice president of sales, notes one trend in recent years is the drive toward more automated systems in cheese plants.

“As much as possible, everything is hands-off now, for the purposes of cost, labor management and sanitation,” Rundle says.

He notes automation is becoming far more prevalent in cheese and dairy packaging, in part from a food safety and reliability standpoint, “Folks want to try to produce some of these products with as little human touching and human interaction as necessary,” Rundle says.

“We’ve really positioned ourselves in a leadership position as far as helping cheese companies, both small and large, to optimize what they do in their plants when it comes to packaging,” he adds.

Rundle adds companies used to purchase more standalone pieces of equipment for cheese packaging, but today more customers are looking for a complete solution to their packaging operations.

Harpak-ULMA is ready with a full-service offering.

“It’s package design, it’s project management, it’s optimization of solution from an integration standpoint. And then, it’s also lifecycle management with what we’re getting into with augmented reality, IoT (Internet of Things) and so forth,” Rundle says.

He notes that Harpak-ULMA also prides itself on offering competitive solutions that lead to a good return on investment (ROI) for its customers.

“We’re trying to move beyond acquisition costs and look at total costs of ownership so, at the end of the day, if this equipment lasts for 20 years, you can ask, ‘How much of that cheese product did you produce in that 20 years, how much money did you make on that cheese product from a profit-margin standpoint?’ That’s all that really matters,” Rundle says.

“We just want to make sure that our customers can keep pumping that product out the door and make as much money selling it as they can,” he adds.

Harpak-ULMA’s success is in part built on its multiyear, multi-tier plan that drives not only increased packaging agility and performance, but resets expectations as to what is possible when it comes to solving some of the most difficult and costly challenges facing modern producers, the company says.

The company has completed the first two phases of the plan, which consist of establishing a smart, connected automation foundation and implementing augmented reality tools for training and maintenance workflows.

Now in phase three, Harpak-ULMA is tying its devices into the internet, making sure machines have the ability to record time-controlled information and even using augmented reality to look deeper into the machine.

In phase four (predictive analytics and performance benchmarking), Harpak-ULMA’s offerings will go beyond day-to-day plant operations and offer data for improving processes and analyzing performance.

• Superior service

Harpak-ULMA recently received results from a market survey it conducted to gain insights into how it can improve, and results overwhelmingly showed clients rank Harpak-ULMA high when it comes to customer service.

“It’s like customer service on steroids,” says Randy Goneau, director of customer service.

“After an equipment sale, we’re all about keeping in contact with the customer and making sure their equipment is running well and meeting all of their expectations,” Goneau says.

He adds that parts, his end of the business, plays a huge role in making sure Harpak-ULMA has the solutions for its customers’ needs.

“If a customer’s equipment is down, we will go to no end to get a part and/or find a solution to get them back up and running,” Goneau says. “If in fact we don’t have a needed part, we will research as to why we didn’t have the part in our stock. Is there something more we can learn about the part?”

He adds that for many companies, their customer service consists of a customer calling in to get a service rep or technician.

“They help you, and then you move on. You got what you needed, you hope, and hopefully your case is solved and it’s done. And on the company’s end, it’s one person handling it and one person taking care of it. Not here. Yes, there’s a person talking to you, logging a technical service request or a technical service report. And then, there’s a meeting that happens four days a week where we have quite a few people represented in there — the VP of engineering and technical service, director of customer service, technicians, service managers. Everyone decides when we’re ready to close a support case. It’s not left up to an individual, it’s everybody,” Goneau says.

“So my vested interest in support cases is to make sure that we have the right parts and inquire if anything goes wrong in the parts area. I’ll approve it when I’m ready to approve it, and technical services will approve it when they’re ready to approve it,” he adds. “So it’s a village. It takes a village to close a service request, and that takes a lot resources and effort. But it pays off down the line because we don’t have a lot of reoccurrences of issues.”

Pete Seward, vice president of engineering and technical service, adds the company offers 24/7/365 dedicated phone support, which can be invaluable, especially this year in dealing with the coronavirus pandemic and less in-person support.

“We have some of the best machine experts, with excellent mechanical, electrical and controls knowledge,” Seward says. “We’re also a company that is leveraging technology wherever we can to get our customers up and running faster or make them run better. So that’s using augmented reality like Vuforia Chalk — whatever we can do to put eyes there and ultimately save our customers money.”

He adds that having the technology available to help customers remotely has been invaluable.

Typically, however, Harpak-ULMA does offer in-person preventative maintenance, as well as programs to offer refresher training with operators and teach customers’ maintenance teams how to properly maintain their machines, Seward says.

“So every three months, we may walk them through to say, ‘These are the things to look for.’ And so, we offer programs like that, and we offer full rebuilds for machines that are much older. If we’ve got the serial number, we usually can do a pretty comprehensive parts review on what would be required,” he says.

Moving forward, company officials say customer surveys and case studies will continue to help Harpak-ULMA improve its services and let its reputation speak for itself.

“We don’t have to say it ourselves, — we’re going to have our customers say it for us,” Goneau says.

CMN

| CMN article search |

|

© 2025 Cheese Market News • Quarne Publishing, LLC • Legal Information • Online Privacy Policy • Terms and Conditions

Cheese Market News • Business/Advertising Office: P.O. Box 628254 • Middleton, WI 53562 • 608/831-6002

Cheese Market News • Editorial Office: 5315 Wall Street, Suite 100 • Madison, WI 53718 • 608/288-9090