|

|||

|

|

|

|

IMAC continues to grow, invests in new culture plant near Denver headquarters

Editor’s note: Welcome to Ingredient Innovation, CMN’s new segment exploring recent innovations and trends in the dairy ingredients sector. For this segment, we will profile a leader in the ingredients industry as well as share updates on mergers and acquisitions and new offerings for cheese and dairy in ingredients — where flavor begins.

By Alyssa Mitchell

|

Photo courtesy of International Media and Cultures |

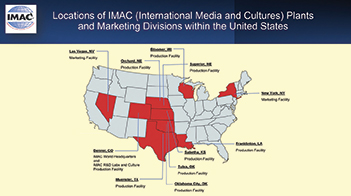

| EXPANDED REACH — From its modest start in Denver, International Media and Cultures has grown to 10 manufacturing plants across the United States. The company currently is investing in a new culture plant near its Denver headquarters to expand specialty offerings for cheese and dairy manufacturers. |

|

| Photo courtesy of International Media and Cultures |

| DAIRY OFFERINGS — Some of IMAC’s key offerings for dairy ingredients include milk silo cultures to improve safety and cheese yields, bulk starter media and anticaking agents. |

DENVER — International Media and Cultures (IMAC) is investing in a new culture plant near its headquarters in Denver as the company seeks to expand its specialty offerings for cheese manufacturers.

IMAC was founded in 1982 by Mali Reddy, who holds a Ph.D. and has received several awards throughout his career for his innovation and research in cheese technology. From its modest start in Denver, Reddy’s vision for IMAC has been to create a research-driven, highly technical company that is dedicated to producing quality, custom-tailored products for use in the dairy and food industries. IMAC has been awarded and obtained more than 150 national and international patents and trademarks for its products and manufacturing processes.

Since its inception, the company has grown to 10 manufacturing plants across the United States. In addition to its headquarters in Denver, the company has facilities in Colorado, Kansas, Nebraska, Wisconsin, Oklahoma, Texas and Louisiana.

The company has affiliate operations in India, Europe and most recently gained a foothold in emerging Latin American markets. IMAC also has branched outside the cheese industry in recent years, exploring new applications for soy, probiotics and bio-animal feeds for the dairy, beef, poultry and aquaculture industries, Reddy notes.

IMAC is a branch of American Dairy Food and Consulting Labs Inc. (ADFAC Labs). In 1982, ADFAC Labs started to service the U.S. dairy and cheese industry, and Reddy says the inspiration to form IMAC came from the desire to service small cheese-producing companies that could not afford formal research and development (R&D) and/or quality control divisions. However, over the years, IMAC’s scope has widened, and today the company services plants of all sizes, he notes.

“When we started, we discovered there was a communication gap between R&D, quality assurance (QA) and technical service departments, and production and marketing departments, even at mega cheese plants,” Reddy says.

This led to demand for IMAC’s services at large as well as small companies, he notes.

“We became successful in the consulting arena, not only in the United States, but all over the world, successfully servicing more than 70 major and world-renowned companies,” he adds.

A key area of focus for IMAC is the pizza industry, Reddy says, adding he has an extensive background in bacterial fermentations and bacteriophages involved in Italian cheeses such as Mozzarella, Provolone, Parmesan and Ricotta, as well as Swiss and yogurt.

Reddy notes pizza operators require specific functionalities for cheese, and it can be a challenge for cheesemakers to implement the specialty custom tailored culture technology required.

“Many R&D departments at cheese plants are not in the business of making cultures. Meanwhile, some culture providers don’t have the resources to accommodate the specific needs of some of these cheese plants,” he says.

IMAC’s facility in Denver was started in part to fill this specific gap, Reddy adds.

“We started our own culture production facility. One advantage we have is our comprehensive understanding of cheese technology, the needs of customers and the technical know-how to modify production technology and processes to produce functional cheeses,” he says.

He adds that Italian cheeses have seen steady demand growth over the years, with exceptional growth in 2020 as pizza was in high demand among consumers during the COVID-19 pandemic.

“The pandemic significantly impacted the pizza trade due to more home delivery,” Reddy says. “At the same time, consumers cared about making sure their food was safe. Suppliers are demanding more tests and third-party oversight for cheese with increased functionality including longer shelf life.”

Other functionalities IMAC focuses on for these types of cheeses include specialty and direct set cultures to reduce browning of Mozzarella and Provolone on pizza (MJF culture), Reddy says. IMAC also offers custom-made secondary starter media and functional cultures to improve yields, flavor, shelf life and overall cheese functionality.

In addition to pizza cheeses, IMAC’s other key offerings for ingredients include milk silo cultures to protect raw milk in silos and improve safety and cheese yields; bulk starter media for Italian- and American-type cheeses; multiple mixed strain cultures; flavor starter cultures; multiple functional anticaking agents; and specialty functional cultures for Spanish-type cheeses such as Queso Blanco and Queso Fresco, Reddy notes.

The company also offers probiotic cultures and bio-available milk-based calcium as well as other major and minor milk minerals, he adds.

“All of these products have been extremely successful in the field,” Reddy says.

He notes safety is paramount for the company’s offerings, and IMAC spray dries its anticaking agents and starter media to ensure functional and safe products.

“Our philosophy is not to let any contaminant whatsoever get into our customers’ plants,” he says. “Whey, nonfat dry milk, modified starches and other ingredients that go into our products are always heat-treated at a low pH and spray dried to eliminate the presence of bacterial spores, pathogenic bacteria, viruses and various other contaminants.”

Now, IMAC is in the process of building a new culture plant in Denver to not only increase its production capabilities, but also to introduce new products to its ever-expanding product line, Reddy notes.

“We are investing several million dollars to produce unique probiotics for the health food industry, retail supermarkets, hospitals and consumers, in addition to our regular and improved cultures and other ingredients for the U.S. cheese and dairy industry,” he says.

The company’s health and food ingredients division will be instrumental in developing specialty health-promoting, probiotic-based natural Ricotta dessert and ready-to-consume portion-controlled specialty aged cheeses, as well as probiotic toppings, Reddy notes.

“IMAC will be actively involved in introducing these products in conjunction with physicians and participating hospitals around the world,” he says.

IMAC also offers consulting and training services to cheese and dairy manufacturers. Reddy notes the company’s headquarters in Denver encompasses training facilities, R&D and product development laboratories.

“IMAC training programs are tailored for American and European cheese industry personnel, with the most efficient, practical and easy-to-implement strategies to produce cheese with minimal or no defects,” he says.

The company offers training classes on protection of raw milk from spoilage bacteria; in-depth starter culture technology, including selection of functional starter cultures; preparation and handling of bulk starters using starter media; bacteriophage elimination technology; and cheese technology specific to a range and variety of cheese types as well as other dairy products including but not limited to yogurt, buttermilk and sour cream.

“We also put a lot of emphasis on improvement of cheese yields through the use of custom starter technology,” Reddy says.

Next year will mark 40 years in business for IMAC, and Reddy says the company has enjoyed its success over the past four decades.

Some of IMAC’s notable achievements include its proprietary spray dried anticaking agents, as well as milk silo cultures, mixed-strain cultures, direct set cultures and flavor starter cultures for various cheeses, Reddy notes.

“Our products are not ‘run of the mill or mediocre,’” he says. “All of these products have made inroads with great success, and our customers are fully satisfied with the proven superiority of our offerings.”

He adds IMAC has several national and international patents demonstrating the company’s aptitude for new research and developing novel and innovative products for the cheese industry.

“In essence, our plans are to introduce more products to the dairy and cheese industry at a rapid pace and improve the customer’s bottom line. Our production, QA, R&D and marketing staff are committed to accomplishing our mission to be a leader in the industry for generations,” Reddy says.

CMN

| CMN article search |

|

© 2025 Cheese Market News • Quarne Publishing, LLC • Legal Information • Online Privacy Policy • Terms and Conditions

Cheese Market News • Business/Advertising Office: P.O. Box 628254 • Middleton, WI 53562 • 608/831-6002

Cheese Market News • Editorial Office: 5315 Wall Street, Suite 100 • Madison, WI 53718 • 608/288-9090