|

|||

|

|

|

|

Dairy Connection offers added value with custom culture blends program

Editor’s note: Welcome to Ingredient Innovation, CMN’s new segment exploring recent innovations and trends in the dairy ingredients sector. For this segment, we will profile a leader in the ingredients industry as well as share updates on mergers and acquisitions and new offerings for cheese and dairy in ingredients — where flavor begins.

By Alyssa Mitchell

|

Photo courtesy of Dairy Connection |

| CUSTOM BLENDING — Dairy Connection Warehouse and Production Manager Patrick Varno seals pouches of culture in one of the company’s three production rooms during a recent custom blend project. The ingredient distributor now offers custom blending and sizing services. |

|

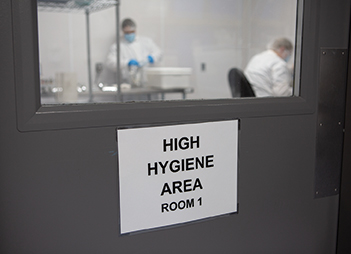

| Photo courtesy of Dairy Connection |

| SAFETY AND HYGIENE — Dairy Connection staff work on a client’s custom blend in one of the company’s three specially-designed production rooms. |

MADISON, Wis. — Dairy Connection Inc., a national distributor of cheesemaking supplies, cultures, enzymes and other ingredients, is offering its customers a new custom culture blends service that brings added value, convenience and potential cost savings.

For more than 20 years, Dairy Connection has served specialty cheese, yogurt and fermented milk creameries nationwide. The company’s small but busy team works diligently to get customers what they need, when they need it, with the highest level of service, says Dave Potter, owner and president, Dairy Connection.

The company currently has 15 employees, and its four-person team of technical specialists has more than 100 combined years of experience in the dairy ingredients industry.

“We’re a family business, and a lot of our customers are family businesses,” Potter says. “We work with a lot of cheesemakers who have generations of family at the company, and we can relate on each of those levels because we’ve been there.”

He’s quick to add that in addition to employees with decades of experience, Dairy Connection also has five employees who participate in the Wisconsin Cheese Makers Association’s Young Professionals group, which is comprised of professionals aged 40 and under.

“We have a wide range of generations, so we’re really connecting across the generations with our customers when it comes to new technology and communication,” Potter says.

While Dairy Connection can serve companies of any size, its niche is in specialty operations that require unique ingredient blends but don’t necessarily have the ability to place large orders.

“That’s really how we got started,” Potter says. “We’re an extension of our current culture vendors — such as Chr. Hansen, Danisco, DSM — we’re serving the clients they aren’t always able to get to. They can’t serve everyone on a small-scale basis, but that’s what we specialize in.”

He adds Dairy Connection also has some larger customers but works with them to provide specialized ingredients and other offerings.

“We have a very quick turnaround — typically same-day shipping — and we don’t require an order minimum on stock products. You can’t always get that with a larger company,” Potter says.

Potter says Dairy Connection’s ability to fill a niche in the industry, combined with the company’s superior customer service, is what makes the company a trusted partner to so many in the cheese industry.

“Our customer service is No. 1 — and customer service can mean a lot of things to a lot of people,” Potter says. “They call today because they needed it yesterday. When you have milk coming in and need to do something with it, I think response time is really important in order to meet the needs of our customers. So they choose us because of our response time and the ease of doing business with us.”

Now, with its custom culture blends program, Dairy Connection looks to delve even further into filling niche needs for its customers — not only for cheese, but also for yogurt and fermented milks.

“We don’t make cultures — we distribute them — but we’ve found a way to add value for those customers by blending certain cultures together to meet the needs of very specific applications,” Potter says.

“We can blend the cultures that maybe have one functionality for flavor, one for texture, one for acidification for that customer’s needs,” he adds. “It gives them more options when developing cheese and other dairy products.”

In addition, with a custom culture, a customer is likely to need only a small amount, Potter notes.

“We have the facility set up to allow for that,” he says. “They may only need a small amount, but they need it to be the same every time. We can provide that for them.”

Particularly with COVID, the industry has adapted, leading to people marketing their product differently but also making it unique and getting noticed, Potter says.

“Our custom culture blends program can help with that,” he says, noting the program is tailored to meet a product’s functional needs and market demand.

“We can make it sized for a specific batch, eliminating at-the-vat measuring, with precise bacteria ratios in every batch,” Potter says, noting this also is important from a food safety standpoint.

The custom blends program eliminates the need for open pouches, reducing waste and risk. The service also lends itself to benefits with co-manufacturing, Potter says.

“Companies don’t necessarily want to share their technical knowledge of what’s going into a culture blend, but we can package that blend for them and ship it to another company without them knowing the specific makeup,” he says. “So there also are some proprietary aspects that we can provide. We do that with large commodity cheesemakers as well — especially those producing specialty cheeses who need that niche service. And I think that will continue to grow.”

Probiotics is another application where custom cultures come into play, Potter says.

“We can custom blend a specific probiotic culture for a yogurt maker — they may only be making small batches, but we specialize in small volumes,” he says.

He adds, however, that Dairy Connection assesses all custom-blend projects on a case-by-case basis, and each proposal undergoes careful evaluation to ensure it is a good fit for all.

Dairy Connection has three production rooms at its facility in Madison, Wisconsin, which the company just moved to in 2019. The facility is more than twice the square footage of the company’s former location three miles north.

“We have all three production rooms going and will probably have to create more. The application and need is there,” Potter says.

“The relocation gave us space to increase our custom blending and packaging operation so that we can offer more opportunities for different types of culture blend products,” he adds. “We’re now able to do some semi-automated packaging, too, which allows us to increase production volumes for customers that require larger amounts of product, produce customized culture blends more efficiently and better service home and hobby cheesemakers’ cultures and enzymes on a small-scale basis for our distributor clients.”

Dairy Connection’s facility is Safe Quality Food- and kosher-certified, with staff trained in Hazard Analysis Critical Control Points (HACCP) guidelines. The company offers complimentary technical assistance and application support, with a 24/7/365 emergency hotline.

“Our technical staff is always ready to answer any product or application questions that may come up, or to help troubleshoot a technical issue that a customer may have at their creamery,” Potter says.

The company also offers training classes and in recent years, pre-COVID, held an annual Swiss Summit in Ohio offering a day of seminars and networking focused specifically on topics related to the manufacture of Swiss cheese.

“It’s not always about selling an ingredient — it’s about supporting what the cheese industry needs in each of the markets we serve. What we need in Wisconsin may not be the same as what we need in Ohio,” Potter says. “You can’t be a one-size-fits-all, so we specialize in what we can.”

CMN

| CMN article search |

|

|

© 2025 Cheese Market News • Quarne Publishing, LLC • Legal Information • Online Privacy Policy • Terms and Conditions

Cheese Market News • Business/Advertising Office: P.O. Box 628254 • Middleton, WI 53562 • 608/831-6002

Cheese Market News • Editorial Office: 5315 Wall Street, Suite 100 • Madison, WI 53718 • 608/288-9090